An overview of what investors should look for in an inventory of methane emissions, including initial and follow-up questions.

Initial questions for engagement

- How do you improve the accuracy of your emissions inventory each year?

- What have you learned from direct measurement of emissions conducted to date? What are the main constraints to increasing direct measurement?

- If not incorporating direct measurements, how do you know your emissions inventory is accurate and that you do not have unidentified problems in your system?

Follow-up questions

- If you are not doing any inventory at all, how are you optimizing operational efficiency without understanding your emissions baseline?

- What percentage of your assets are you directly measuring annually and what percentage are you measuring using emission factors?

- Who in your organization is directly accountable for measuring methane emissions?

- What are your plans to increase the level of direct measurement in your emissions inventory process? By when?

Overview

Under the oft-heard principle of “what gets measured gets managed,” the first step for a company in reducing methane risk is to understand its baseline methane emissions. Creating a robust and accurate inventory of emissions and sources is a prerequisite for a company to:

- Spot opportunities to improve operational efficiency and financial gain;

- Accurately gauge methane risk; and

- Create emissions reduction plans and targets

Inventory

Embodying three principles can ensure a robust measurement program. Measurement should:

Be comprehensive

All potentially material sources of methane emissions should be part of an emissions inventory, including emissions from joint venture partnerships.

Employ frequent observation

Fugitive emissions, or leaks, have been shown to often be intermittent. Because of this, frequent monitoring is therefore suggested to detect and measure these emissions (and repair them).

Use rigorous quantification

Companies are encouraged to incorporate direct measurement of emissions whenever possible, as opposed to estimating emissions in a desktop analysis. Direct measurement provides for much greater accuracy in emissions data, particularly for fugitive emissions.

Companies will likely rely on a combination of estimates and direct measurement to develop their emissions inventory. The methodologies companies employ to estimate non-measured emissions should be made available so that investors may compare relevant datasets across a given industry and understand uncertainty factors. Today, many companies do not measure their emissions at all, or rely strictly on generic estimates from historic emissions factors. Leading companies will incorporate robust direct measurement into their processes to build stakeholder confidence in the accuracy of reported emissions.

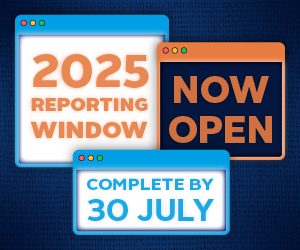

Performance assessment tool

The below table is designed to help investors understand where a company falls on the spectrum of methane performance and enable investors and operators to identify concrete next steps to improve performance over time as they move from beginner to intermediate and onto expert level methane management. A performance assessment table is included in each of the main sections of the report.

| Beginner | Intermediate | Exert |

|---|---|---|

| Estimates emissions using generic emissions factors (which are less accurate) in a desktop analysis. | Creates a strategic plan for how and where measurements need to be taken and has begun using some direct measurement. | Implements a policy where every facility is measured 1x or more every 3 years (vs. doing leak detection quarterly). |

| Developing plans to take measurements within one year. | Uses direct measurements to develop company-specific emission factors (more accurate than generic industry factors) to better estimate company methane emissions either at the component or facility level. | Uses company-specific emissions factors when estimating emissions by source. |

| Companies support international science efforts by sharing their measurement data. | Companies join international science efforts, provide site access for measurements and funding. |

Emissions inventories for compliance versus investor reporting

Certain countries, like the U.S., Canada and Australia, have regulatory requirements for operators to report methane emissions data to policymakers. Such compliance reporting programs can have fairly prescriptive guidelines for how to estimate emissions, may not require or allow direct measurement, and often are not inclusive of all sources, thus producing incomplete data. The guidelines can also rely on the use of outdated emissions factors which can often be inaccurate by several orders of magnitude.

Emissions inventories created for investor reporting can be an opportunity for companies to develop more accurate and complete information, particularly by including more direct measurement. In general, compliance reporting is strictly focused on quantitative emissions data, and provides little to no qualitative details about how a company is planning to reduce emissions through adoption of best management practices of setting of targets.

In December of 2015, Total, ENI, EDF and others announced an effort to better understand global oil and gas methane emissions. This data can help narrow uncertainty about global oil and gas emissions and help policymakers and investors better understand this risk. This effort is open to other companies to join to help fund the research and provide access to assets for measurements. Additionally, as companies incorporate more direct measurements that data can be shared with this international science effort.

Download the full report

-

An investor's guide to methane

February 2017

An investor's guide to methane: Engaging with oil and gas companies to manage a rising risk

- 1

- 2

- 3Currently reading

Measure

- 4

- 5

- 6